Gearing up for wide speed ratios

Our FG microspeed units can handle tough applications. They are extremely resilient to vibrations and increased ambient temperatures. Microspeed drives consist of main and microspeed motors that are connected by means of microspeed gearboxes, which enables them to be used for wide speed ratios in rugged, simple and cost-effective solutions. They provide for:

- maximum positioning accuracy

- high switching frequency

- movement of large masses in short cycles

- implementation of extremely high speed ratios of up to 500:1.

Product information

The benefits at a glance

-

- Highly robust drive

- Extremely resilient to vibrations and increased ambient temperatures

- Rugged alternative to inverter-controlled AC motors

- Wide speed ranges

- speed ratios up to 500:1

- wider mechanical speed range between the main and the positioning speeds than pole-changing motors

- Up to 4 fixed speed steps when pole-changing motors are employed

- Short cycle times

- Maximum positioning accuracy

- Highly robust drive

Technical data

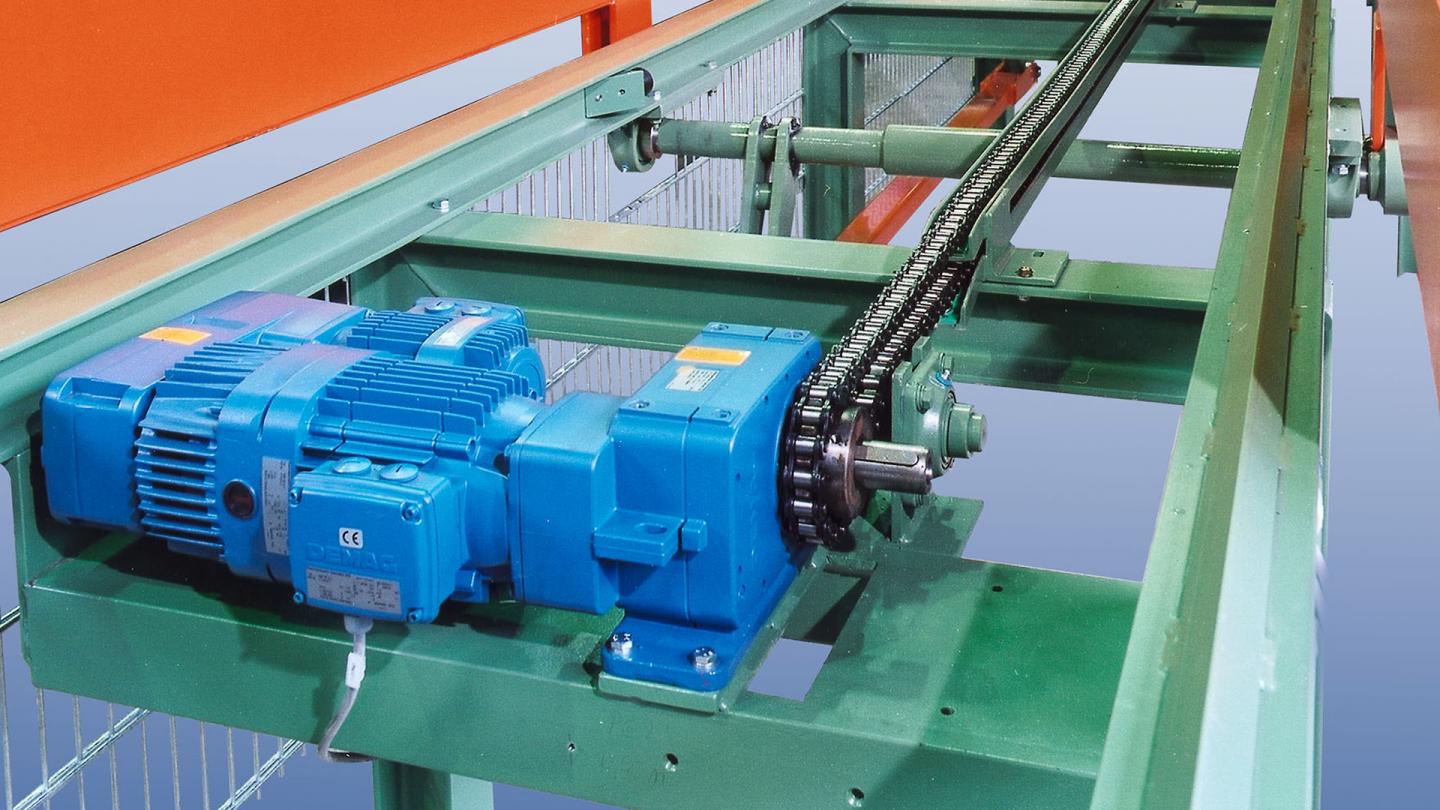

- FG microspeed drive with main and microspeed motors (connected to each other via a mechanical microspeed gearbox)

- Output shaft runs either at the speed of the main motor or at the speed of the microspeed motor (reduced by the transmission ratio of the gearbox)

- Conical-rotor brake motor as the main motor (due to the axial movement of its rotor)

- Motor brake functions as a coupling in microspeed motor mode

- Microspeed motor can be a KB or a Z motor – also for inverter operation

- Microspeed gearbox offers finely graded transmission ratios – from 4 to 125

- The overall transmission ratio is specified together with the selected motor speeds

- U and Z configurations

- The microspeed drive can be combined with the offset, angular and helical gearboxes with coupling connection