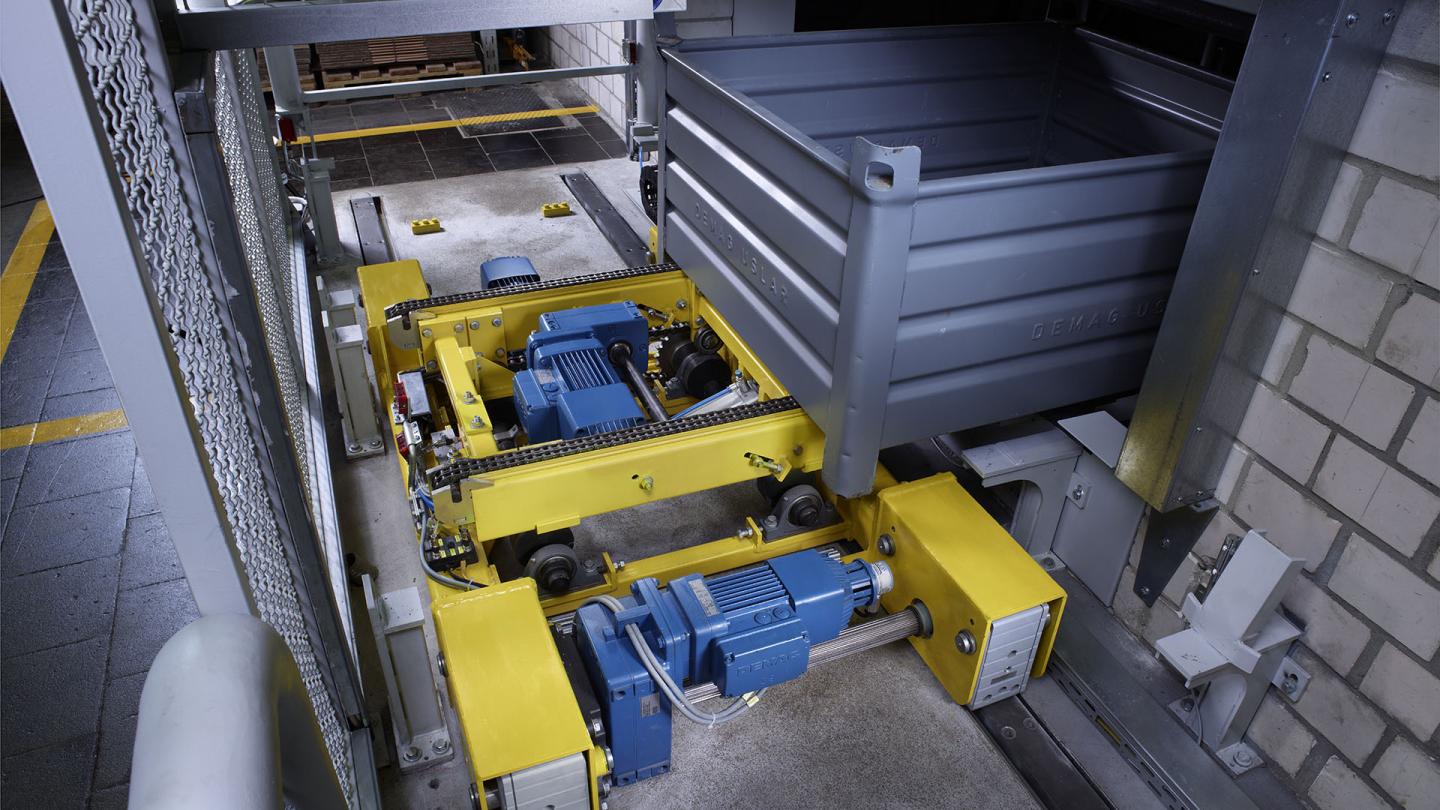

Modular system for tailor-made solutions

Our DRS wheel block system is a versatile travel wheel system and is perfectly integrated into our modular drive system. Eight finely graded sizes with load capacities of up to 40 tonnes per wheel provide the right wheel block for every application. And the large selection of travel wheels and special wheel designs enable them to be adapted to almost any travel rails and operating conditions. Cost-effective and ready to install. Further strengths:

- high performance range and maximum load capacity

- many travel wheel shapes as standard as well as customer-specific designs

- 4 variants for connection to the customer’s superstructure

- high-quality housing with optimum protection of the travel wheels and bearings

- high rigidity

- direct connection of optional accessories

- laser alignment system for wheel blocks on multiple travel units.

Product information

The benefits at a glance

Exact configuration

- 8 sizes with load capacities per wheel from 2.75 tonnes to 40 tonnes

- Wheels of various shapes and designs – made of spheroidal-graphite cast iron (GGG 70), polyamide or featuring Hydropur tires

- A: Guided on both sides by flanges for rail systems

- B: Wheels without any flanges, optionally fitted with lateral guide rollers, also with concave shape or contour to customer specifications

- D: Wheels guided by a flange on one side for units running at floor level

- E: Larger diameter wheels without a flange for increased ground clearance

- S: Wheels of prismatic, trapezoidal or concave shape for guided applications

- F: Flangeless wheels with a Hydropur tire for high acceleration & quiet running characteristics

- C: Flangeless, concave polyamide wheels for quiet operation that is kind to the runway

Many connection variants

- Prepared mounting surfaces for virtually any connection: from top and end connection arrangements with bolted and welded connection elements, to side and pin connection arrangements

- K: Top connection

- B: Pin connection

- S: End connection

- W: Side connection

Tailored solutions

- Complete travel units with precisely matching geared motors

- High rigidity thanks to special stiffeners

- High ground clearance for wheel blocks thanks to the compact system design – also for complete drive units with their gearbox concept designed to match the wheel load

- Horizontal guide roller arrangements and buffers in various sizes and designs (optional)

Very easy assembly

- Housings ready for direct connection to superstructures

- Simple connection to superstructures thanks to tight design and position tolerances of the housing and precise geometry in all planes

- Laser alignment system for simple and precise alignment of the wheel blocks

- Simple wheel replacement without the need for re-alignment of top connection thanks to patented asymmetrical housing

- Wheel blocks can also be moved and aligned laterally after they have been installed in hollow sections and beams (for top, end and pin connection arrangements)

Require little maintenance

- Cast housing enclosed on five sides reliably protects the travel wheels against any mechanical influence

- Generously dimensioned grooved ball bearings which are lubricated for life, tapered roller bearings from size DRS 250

- Travel wheels made of self-lubricating spheroidal-graphite cast iron (GGG 70) for low friction and high resistance to wear

- Integrated wear indicator on wheels with flanges for remote visual diagnosis

Technical data

| Size | Max. load capacity | Travel wheel dia. | Weight | Dimensions [mm] | ||||

| [t] | [mm] | [kg] | a1 | b1 | b2 | c1 | h1 | |

| DRS 112 | 2.75 | 112 | 7.3 | 190 | 47 | 80 | 96 | 131 |

| DRS 125 | 5 | 125 | 9.9 | 220 | 60 | 80 | 98 | 147.5 |

| DRS 160 | 7 | 160 | 18.3 | 275 | 65 | 89 | 110 | 187 |

| DRS 200 | 10 | 200 | 35.7 | 340 | 65 | 101 | 130 | 238 |

| DRS 250 | 16 | 250 | 62 | 385 | 75 | 110 | 150 | 281 |

| DRS 315 | 22 | 315 | 117 | 470 | 90 | 130 | 180 | 349.5 |

| DRS 400 | 30 | 400 | 201 | 580 | 110 | 155 | 210 | 440 |

| DRS 500 | 40 | 500 | 352 | 700 | 110 | 170 | 240 | 566 |

Options and accessories

- Torque brackets for connection to offset and angular geared motors

- Horizontal guide rollers

- Buffers in various sizes and designs

- Rail sweeping system

- Solutions for high temperature applications

- Travel wheels of hardened design