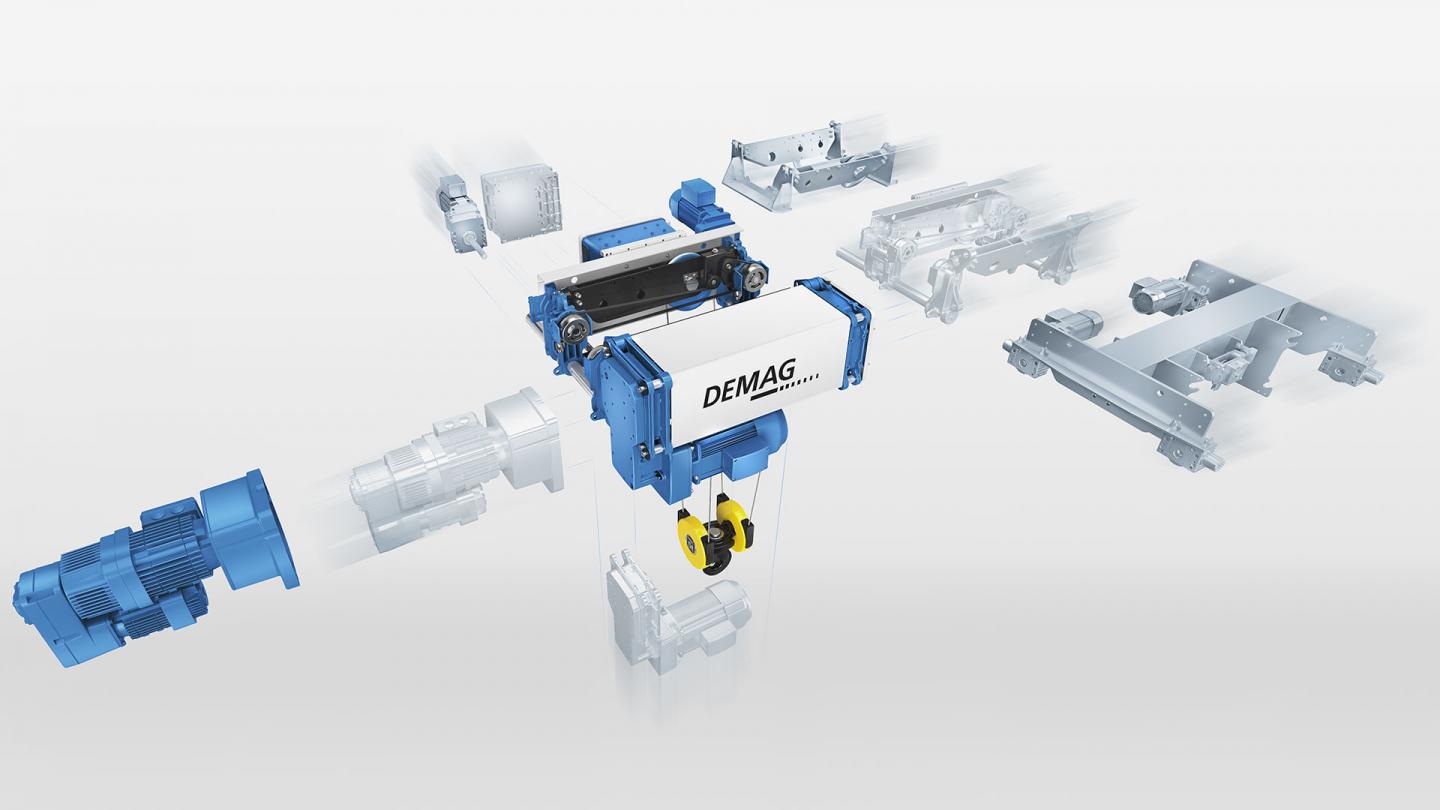

One rope hoist. Two designs. Many possibilities.

Individual needs require specific solutions. That is why we developed the DMR modular rope hoist. You can benefit from ground-breaking flexibility in all types of applications: from stationary installations to crane systems. For the first time, a rope hoist can be built either in a C-design or co-axial design utilizing one basic technology. The extraordinary wide range of possible DMR applications can be extended thanks to smart interfaces and corresponding fittings and accessories.

Choose for yourself:

- C-design or co-axial design

- Five sizes with load capacities up to 50 tons

- Various application types: foot-mounted hoist, low-headroom travelling hoist, double-rail crab and standard-headroom travelling hoist

- Control system: smart SafeControl system, conventional contactor control or provided by the customer

- Variable or two-stage switching elements

- Control concept: wired connection or radio control

Product information

The benefits at a glance

High variability thanks to modular design

- Modular design for rope hoist configuration to meet individual needs

- Broader range of applications with one basic technology

- More sizes with higher load capacities

Two designs for all requirements

- C-design: optimised for crane applications with compact overall dimensions and reduced approach dimensions

- Co-axial design: versatile integration into virtually any construction, optional mechanical microspeed unit for even greater precision

Planning and application flexibility

- Application types: foot-mounted hoist, low-headroom monorail hoist, double-rail crab, standard-headroom monorail hoist

- Smart interfaces for many freely selectable fittings and accessories

- High operating safety and reliability

- Alternatively: contactor control or control system provided by the customer

Further benefits

- Rugged and reliable mechanical components

- High traction with double-wheel drive (DualDrive), optionally with a second travel motor (DualDrive Plus) for EK-DMR

- F10 mechanical microspeed for co-axial design: two separate conical-rotor motors for main and creep lifting motions for even more precise load positioning

- Remote diagnostics in real time with StatusControl

Technical excellence down to the last detail

Hoist motor

High performance and precision

The DMR rope hoist drive employs a high-performance cylindrical-rotor motor to ensure precise lifting and lowering motions. It achieves motor outputs of up to 45 kilowatts. The rope hoist in co-axial design positions loads with even greater precision with its optional F10 microspeed unit. The drive consists of two separate conical-rotor motors for the main and creep lifting motions. The motors offer outstanding braking capacity as well as automatic braking if the power drops or the motor is switched off. All motor cables feature plug-and-socket connections for plug-&-play operation.

Frequency-controlled or pole-changing operation

You also have a choice of motors: hoist motors for variable speeds or two-stage speeds.

Coupling

Long service life and ease of maintenance

The coupling between the motor and gearbox absorbs sudden motor forces for a longer rope hoist service life. In addition, DMR can be easily retrofitted with a rotary encoder. If the motor needs to be changed, the gearbox oil does not have to be drained.

Gearbox

Efficient oil lubrication

The DMR gearbox provides for long maintenance intervals thanks to its efficient oil lubrication. Its enclosed design offers protection against external factors. DMR also requires 30 percent less oil.

Rope drum

Low wearing and versatile

The rope guide is made of tough, acid-resistant plastic and boasts extremely low wear. The rope can accommodate inclined pull up to an angle of 4 degrees without touching the rope guide.

Two-piece protection

The cover for the rope drum consists of two parts. All rope hoists are supplied with vertical panels to protect the drum as standard. If required, they can also be supplied with a horizontal cover for the rope drum.

Housing

Light-weight and tough design

The housing of DMR hoist unit sizes 3, 5, 10 and 16 weighs much less than those of previous models. Thanks to high-quality powder coating, which provides optimum protection against corrosion, all DMR rope hoists can also be operated in aggressive environments.

Bottom block

Safety and low wear

Larger rope sheaves in the top and bottom blocks significantly reduce rope wear also over longer periods of operation. The two-piece hand guard with moving plastic elements protects the operator against accidental contact. If necessary, it also allows wearing parts to be quickly replaced without the need to remove the rope. Two handle recesses make it easier to handle and guide the bottom block.

Control

Radio control: high performance

We also offer our customers maximum flexibility and freedom of choice for their specific control needs. Our high-performance DRC D3 radio control system permits maximum freedom of movement and ease of control. The new generation of radio transmitters can be used for up to five days of uninterrupted operation. Three transmitters can be paired with each receiver for simple transfer of control at the press of a button. Up to 40 systems from our D3 generation of radio controls can be operated in close proximity to each other without any mutual interference. High safety standards are satisfied by frequency hopping and listen-before-talk operation.

Wired connection and ergonomic

For control from the ground, the DMR rope hoist works with two control units – depending on the control system electric equipment. For use with our SafeControl smart control system, our DSE 10R control pendant provides for safe and reliable control of the rope hoist and facilitates fatigue-free operation thanks to its ergonomic design. Rope hoists that have contactor controls are operated via DST control pendants.

Travelling hoist

Smooth frequency inverter control

DMR travelling hoists are fitted with frequency inverter-controlled cross-travel motors as standard and travel with variable speeds from 3 to 30 m/min. They offer precise positioning and smooth travel that is kind to the runway – supported by high-strength steel travel wheels and guide rollers. If required, we can also supply DMR low-headroom and standard-headroom travelling rope hoists and double-rail crabs with two-stage travel speeds.

Lighter and more versatile

The DMR trolley is a compact, light-weight unit thanks to the use of high-performance pressure rollers. DMR rope hoists can also be supplied with counterweights, as required.