Demag chain hoists – high productivity, efficiency, safety and reliability

Our chain hoists meet all the requirements of state-of-the-art hoist units, such as high productivity, efficiency, safety and reliability, and give you the certainty of a secure long-term investment. We develop and produce materials handling solutions for all industries and companies of all sizes, from small workshops to major industrial corporations.

Thanks to our expertise and proximity to the customer, we have developed electric chain hoists that can lift almost any type of load with a high degree of safety with fast or individually adapted lifting movements.

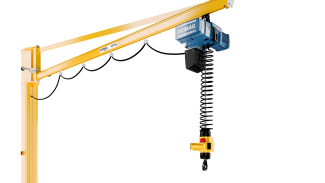

Our chain hoists are electrically driven and can be moved electrically or manually by means of trolleys, depending on the application. In addition, a Demag electric chain hoist can of course also be operated in stationary position or on a crane.

High level safety with our electric chain hoists

Thanks to robust and proven electronic control, the electric chain hoists of our DC product line offer improved safety compared to conventional controls. The electric chain hoists satisfy at least Performance Level c and Category 2 to EN ISO 13849-1 for the safety-related functions specified in DIN EN 14492-2.

You can rely on our chain hoists to handle your load. The standard operating limit switches, 24 V contactor control and slipping clutch secure your load in every application.

Certified lifting technology

- DC electric chain hoists satisfy the relevant provisions of

- Machinery Directive 2006/42/EC

- Low Voltage Directive 2006/95/EC

- EMC Directive 2004/108/EC

- BGV standards

Fully featured as standard

A chain hoist always follows a useful overall concept. From crabs and travelling hoist units to the electric trolley to the chain, we always use the highest quality. Many safety features and components that enhance ergonomics are built into our electric chain hoists as standard. We make lifting and lowering your load as smooth, efficient and safe as possible.

Quality for greater efficiency

A gearbox service life that is rated 20% higher according to the FEM classification is a standard feature of many versions of our DC electric chain hoists. This gives you the certainty that the chain hoist service life can be guaranteed for a significantly longer time. In addition, the generous dimensioning of all components ensures the constant availability of the electric chain hoist.

The equipment can be easily put into operation and offers optimum ergonomics thanks to our Plug & Lift and Plug & Drive system. The electrical connections are of plug-in design. Control cable length or position of pendant controller can be flexibly adjusted without the need for any wiring. Ergonomically designed DSC and DSE pendant controllers with low-fatigue actuation force make load handling with our chain hoist as convenient as possible.

The folding suspension bracket also makes it easy to hook the electric chain hoist into the trolley. Infinitely variable adjustment of trolleys to the flange width facilitates fast commissioning.

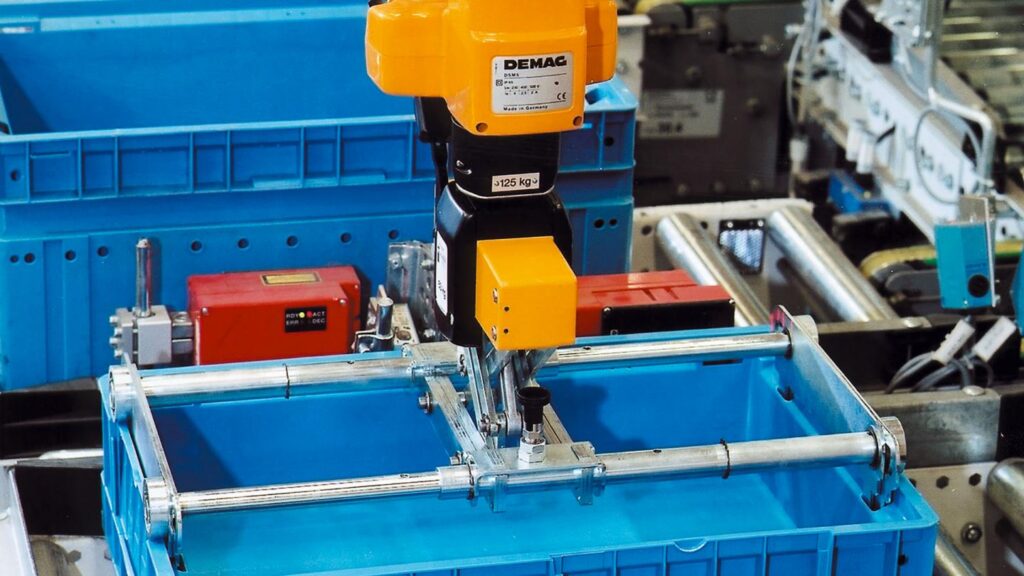

Demanding application solutions

A DC electric chain hoist can support you in almost any application – also thanks to standardised special solutions. Both in stationary use or fitted with a trolley for use on crane installations, slewing jib cranes or on the KBK light crane system. The combination of several chain hoists can facilitate the handling of a load immensely.

Applications with extended hook centre distance for BigBag load bars are possible with our KLDC travelling hoist for big bags. For travel on curved track, our electric chain hoist mounted on a DDC articulated monorail hoist is the ideal solution. Two or four DC units can be operated in tandem. Double chain hoists that have two mechanically synchronised chain lead-offs are particularly suited for handling long materials and for spreader operation. Our LDC-Q quadro chain hoist helps to handle loads that have a particularly large surface area with four electric chain hoists.

In the wind turbine applications, the DC-Wind offers you hook paths of up to 180 metres with a long service life.

We offer a wide range of load attachments to secure loads to meet the various handling requirements.

Your benefits when you buy a DC electric chain hoist

- Individual customer solutions from our comprehensive product range

- Versatile and fully equipped as standard

- Proven technology

- Tough and reliable

- High level of safety and reliability and long service life

- Simple commissioning

- Ergonomic operation

- Minimum maintenance requirement and easy to service

Our chain hoist standards are reflected in ergonomics and safety. Your load is handled safely, efficiently and economically by our electric chain hoists.

Technical data

Gearbox

- Maintenance-free for up to 10 years

- 20% longer service life compared with FEM 2m, with a service life of 1900 full load hours thanks to FEM group of mechanisms classification 2m+

- Reduced operating noise and smooth operation thanks to helical gearing in all gearbox stages

Controls

- 24 V contactor control

- Elapsed operating time counter

- Operating limit switches (upper/lower for DC-Pro)

- DC 16/25 sizes fitted with geared limit switches as operating limit switches with four contacts for fast-to-slow and final cut-off

Alternatively

- Infinitely variable inverter control

- Conventional direct and contactor control

Brake

- Maintenance-free for up to 10 years (up to 5 years for DC-Pro size 10-25)

- No brake adjustment required

- Short and gentle run-on paths

- The brake is impervious to poor weather and operating conditions (enclosure features double encapsulation)

Slipping clutch

- Maintenance-free for up to 10 years

- Brake arranged in front of the slipping clutch in the load-bearing arrangement

- Reliable protection against extreme overloads

- Harmful continuous slipping eliminated thanks to speed monitoring

Round-section steel chain

- High-strength, ageing-resistant material with a high degree of surface hardening

- Galvanized and additionally surface-treated to protect against hostile influences

- Optionally available with additional corrosion protection, for foodstuffs and extremely dusty applications

Chain collector box

- Articulated attachment, made of tough, flexible and particularly impact-resistant plastic

- Bags and sheet metal chain collector boxes for longer hook paths

- Hook paths are possible up to 180 m

Suspension bracket

- Suspended to allow for pendulation

- Small hook dimension C for optimum headroom

Housing

- Tough and weight-saving aluminium housing of compact and modern industrial design

- UV-resistant powder-coated finish, insusceptible to knocks and scratches

Chain drive

- The chain drive consists of highly wear-resistant materials for a long service life, suitable for foundry applications as standard

- Quick and easy replacement of the entire chain drive without the need to remove the motor or housing parts

Height-adjustable pendant controller

- The length of the control cable can be infinitely varied for a hook path range of 2-5 m, 5-8 m and 8-11 m

- The length of control cable that is not needed can be stored under the service cover

- The control system and control cable are rated for electric travel applications in 3 axes

Hoist motor

- Robust and durable high-performance motor with large safety reserves even at high ambient temperatures and in prolonged operation

- Two lifting speeds (F4)

- 60% cyclic duty factor, 360 starts/hour

- Insulation class F

- With thermal protection, depending on design

Reeving

- Load capacity up to 1,000 kg with only 1/1 reev