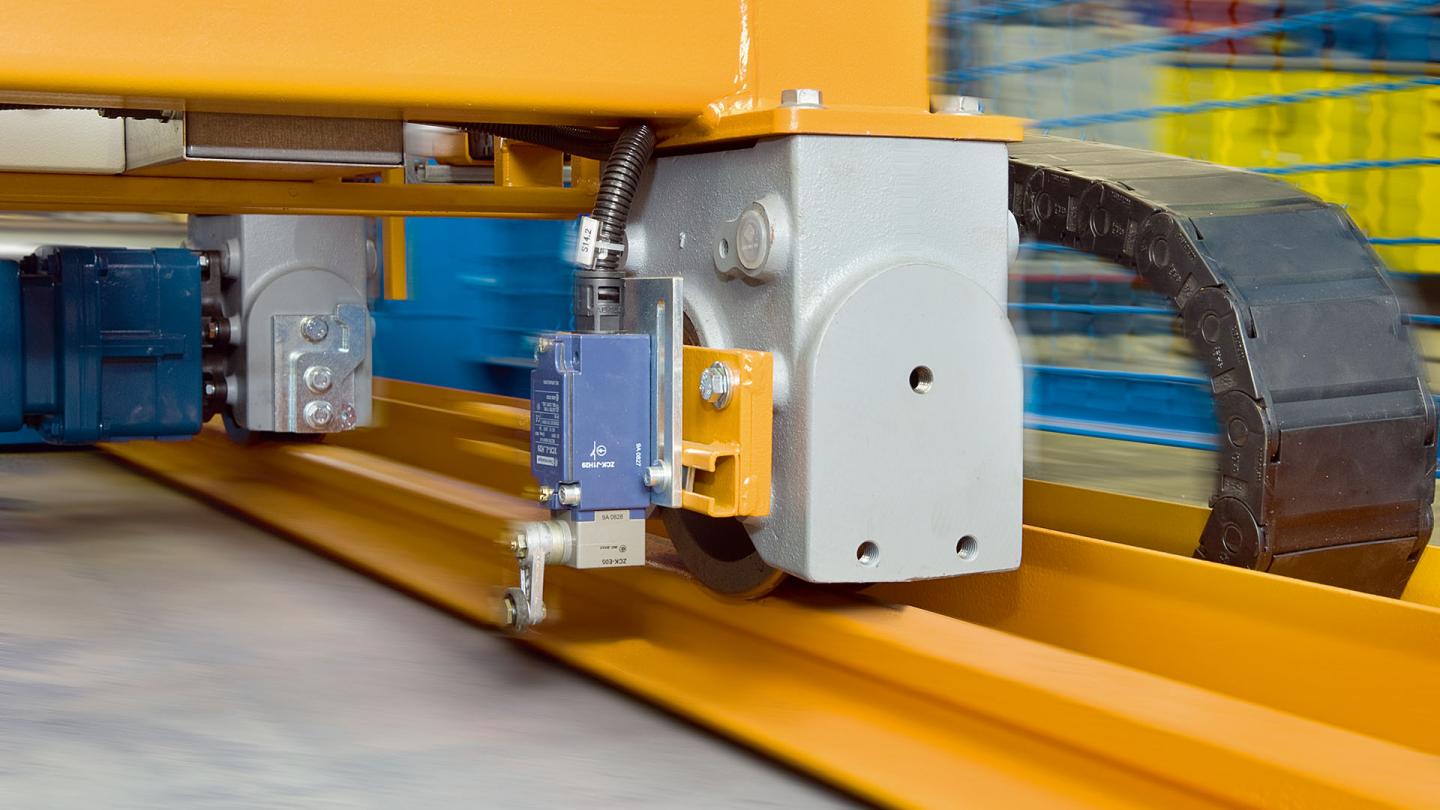

The system that is ready to install for a perfect fit

Using our LRS travel wheel system, you can meet your drive requirements quickly and reliably for transport, feed, transfer, distribution or merge applications. We can supply you with the travel wheels and drive units to suit every application. Ready to install, tried-and-tested designs at extremely attractive prices. What other benefits does the LRS travel wheel system offer?

- Suitable for wheel loads up to 6.5 tonnes and travel speeds up to 240 m/min

- High-quality sheroidal-graphite cast-iron housing

- 5 connection surfaces provide for a multitude of connection variants

- Versatile thanks to the modular design

- Also ideal for OEMs

- Maintenance free

Product information

The benefits at a glance

-

Flexibility

- Modular system to meet practical design requirements

- Three sizes available for loads up to 6.5 tonnes and travel speeds up to 240 m/min

- Ideal for engineers who want to build their own solutions for a wide variety of applications (simple selection of components)

- Can also be extended quickly and cost-effectively at a later date

- For push-travel operation or fitted with offset and angular geared motors as individual or central drive units

Cost-effective implementation

- Attractively priced standard modules for short delivery times with high availability

- Consistently high quality thanks to reliable series production

Tailored solutions

- High ground clearance for wheel blocks thanks to the compact system design – also for complete drive units with their gearbox concept designed to match the wheel load

- Flangeless travel wheels with a Hydropur tire for quiet running characteristics also with high acceleration

- Travel wheels made of spheroidal-graphite cast iron (GGG 70) with vibration-damping characteristics for high-speed operation which is particularly gentle on the rail

- Comprehensive range of gearbox sizes and travel motors

Wide range of mounting options

- Horizontal guide rollers

- Buffers

- Pin connection set

- Rail sweeping system

- Laser alignment jig

Other features

- Maintenance-free, patented travel wheel bearing arrangement

- Gearbox and travel wheel connected via a hollow shaft with involute splines and optimum matching torque bracket

- All travel wheels have hub splines to DIN 5480

- Travel units fitted with the LRS system offer good ground clearance for travel on rails at ground level

- Included in the scope of delivery: high-tensile bolted connections with special surface protection

Technical data

LRS travel wheel system dimensions

| Size/ travel wheel *) |

Max. load capacity | Travel wheel dia. | Weight | Dimensions [mm] | |||||

| [t] | [mm] | [kg] | l1 | d1 | hA / hF |

b1 | b2 | ||

| LRS 200 A | 2.5 | 175 | 15.3 | 250 | 175 | 204.5 | 52 | 70 | |

| LRS 200 F | 1.2 | 200 | 15.1 | 200 | 217 | – | 70 | ||

| LRS 250 A | 3.5 | 220 | 27.6 | 306 | 220 | 255 | 55 | 80 | |

| LRS 250 F | 1.7 | 250 | 26.7 | 250 | 270 | – | 80 | ||

| LRS 350 A | 6.5 | 315 | 63 | 450 | 315 | 349.5 | 65 | 95 | |

| LRS 350 F | 3.0 | 350 | 65 | 350 | 367 | – | 110 | ||

- A = flanged travel wheel made of spheroidal-graphite cast iron

- F = travel wheel fitted with Hydropur tyre

Please refer to the DRS travel wheel system brochure (download) for further technical data and dimensions